Type : Semi-auto Dry Mix Mortar Plant

Capacity: 20TPH

Country and Date: installed 2016 at Kosovo(Serbia)

Process Flow:

Raw Material Preparation :

The user purchase dry sand and cement directly, then all the powder material could be lifting into silo by the bucket elevator first ; the additive will be scaled and distributed in advance.

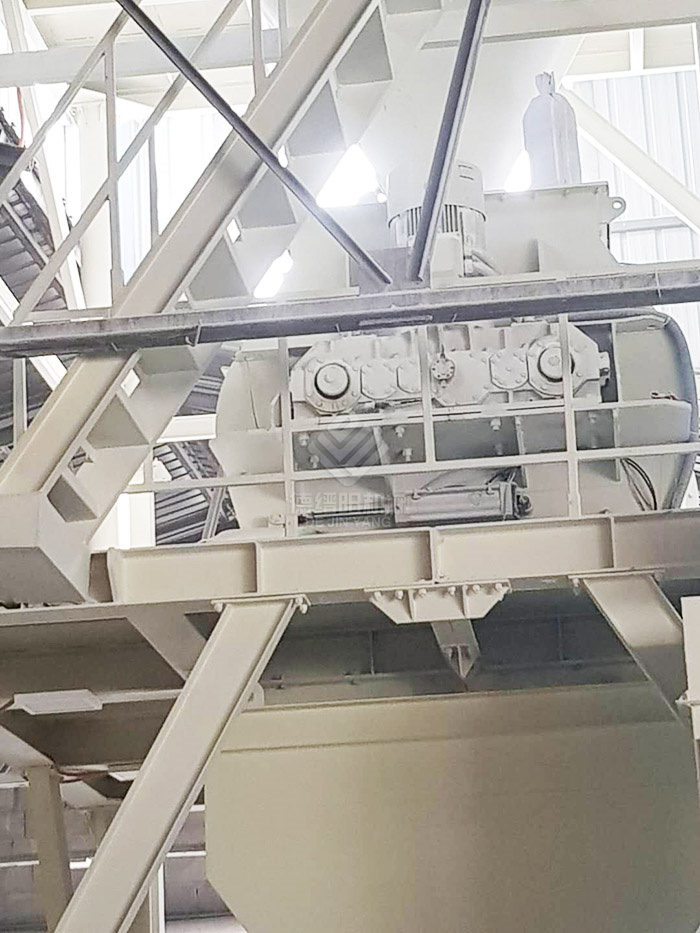

Transferring &Weighting& Mixing Raw Material:

The basic powder material of sand ,cement,lime powder will be conveyed into weighing hopper (installed on the ground)by screw conveyor ,will be lifting into pre-mix hopper(on second steel platform) by indoor bucket elevator ,at the same time there is one labor to feed the additives manually into the bucket elevator’s feeding port for per batch mortar production .Then scaled material will be dropped into mixer through pre-mix hopper.

Packing of end product :

The mixed mortar will be dropped into the end-product hopper first . The auto packing machine installed under of the end-product hopper to improve the packing capacity.Then valve port packing machine work off ,the full bag will be transferred to warehouse by belt conveyor.

Features of this project :

1)Worker Required: 3-5 labors

2)Environmentally Friendly: Adopt Pulse Dedust Filter& bag filter dedustor

3)Measurement: Accurately Batching

Semi-Automatic Dry Mix Mortar Plant could produce 10t~20t capacity per hour ,you may consider this design according to your workshop ,local market situation . It is much efficient cost for the larger capacity .

Cell Phone: +86 15137175832

Whatsapp: +86 15137175832

Email: sunnydjy823@gmail.com

efficientservice@outlook.com

Address: Dejinyang company