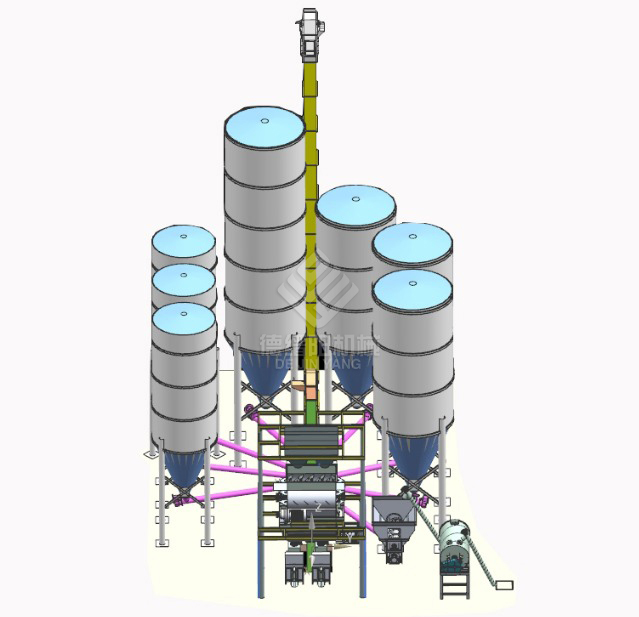

Component of Thermoplastic Road Marking Paint Production Line

The thermoplastic road marking paint production line,all called hot melt coating production line or hot melt reflective coating production line, it is mainly composed of stirring main engine,finished warehouse,screw conveyor,batching weighing silo,bucket elevator,steel frame structure,filling oil system,pneumatic valve mouth packing machine,raw material silo,electric control cabinet ; ribbon mixer, oil filling pipe, oil filling system and pneumatic valve mouth packing machine,the above equipment are main part of hot-melt reflector line paint production line;it also can be equipped with high efficiency dust removal and other related equipment according to customer requirements.

Introduction of Thermoplastic Road Marking Paint Plant

1 ) . Road marking paint mixing equipment /hot melt coating production machine is fast speed mixing , stir with multi-l ayer spiral belt , overall movement of materials, high speed and high yield, the average mixing time is 5-10 minutes ;

2 ) . Multi-usage, can produce solvent at room temperature, heating solvent traffic coatings road marking paint, hot melt type reflective road marking paint, spike type vibration reflective marking paint, water-based reflective road marking paint, etc ;

3 ) . Low maintenance rate, bearing on both ends of the mixer, materials are not easy to enter, equipped with reducer and maintenance rate ;

4 ) . High mixing uniformity, multidirectional movement of materials, multi-layer spiral belt, stirring without dead Angle, high uniformity and good quality;

5 ) . Small footprint, automatic feeding device, improve work efficiency ;

6 ) . U-type/O type tube structure, stable operation, low noise, long service life and wide application scope;

7 ) . Use the inner and outer layers of the inner shell to bring back stirring, no dead Angle, fast mixing speed and high evenness;

8 ) . The marking paint mixer adopts the screw lifting/gladiator to raise the material, the feeding port and the ground level are smooth, the feed is convenient;

The Application of Thermoplastic road marking paint

Hot melt reflective marking paint/ thermoplastic coating paint is mainly used for roads above Grade 2 and the highway. The thickness of the marking coating is (1.0 ~ 2.5) mm. There are reflective glass beads mixed in the paint. Line construction, surface sprinkle reflective glass beads. This line has a good night reflective properties, long service life, according to the traffic flow of highway construction of various types of road marking paint demand estimates, the small and the paint itself may be, generally up (2 ~ 3 years). Hot-melt coating construction requires special heating equipment. The second re-coating of the old markings, the first eradication of the thick old coating can be applied.

Advantage Features of Hot Melt Coating Paint/ Thermoplastic Road Marking Paint

Hot-melt road marking paint using the thermoplastic synthetic resin, the hot-melt paint has a quick-drying, the use of synthetic resin hot melt, so that the marking and road adhesion firm. Hot melt reflective road marking paint generally consists of thermoplastic resin, pigments and fillers, reflective materials and other additives. Hot-melt coating powder at room temperature. Components without solvent volatiles. Construction heating it melts, and then use special equipment coated on the ground, relying on physical condensation solidification film. For hot melt road coatings, the fluidity is a very important technical indicator during construction.

Parameter of Thermoplastic Road Marking Paint Production Line

Main Equipment | Parameter |

Liquid FeedingMechanism | Volume 150L, ingredient error ≤ 300grams, the ingredient warehouse is 304 stainless steel, the rest is ordinary steel ; |

Powder Feeding Mechanism | Double helix tilt feeding, 3kw motor; Level push material, 1.5kw motor; |

Blender | Volume 1500L, 15KW Motor; Stirring speed 25 r / min Wall thickness ≤4.5 mm, Top sealing plate≥2.5mm, Stir Blade Thickness ≥7.5mm, Blender material : ordinary steel ; |

Mixing Type Of Hopper | Volume 1500L, 3KW Motor,Storage tube diameter 219mm ; |

Filling Machine | 3KW Motor,Automatic weighing, the error ≤ 300 grams (Material: ordinary steel) |

Cell Phone: +86 15137175832

Whatsapp: +86 15137175832

Email: sunnydjy823@gmail.com

efficientservice@outlook.com

Address: Dejinyang company