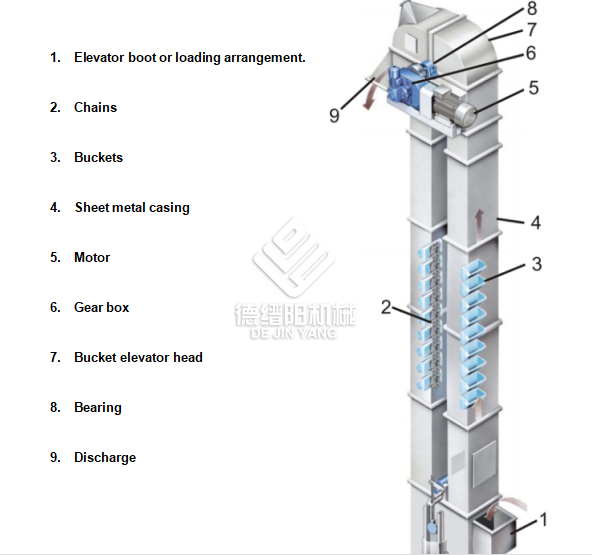

Introduction of bucket elevator

The latest design of bucket elevator, the lower arc design, greatly reduce the residual material. Bearing the seal, the use of 12 mm thick steel plate and frame seal, bearing base through special processing, guarantee the seal and bearing contact closely, make sure the dust can't cause pollution from inside to outside, bearing lock caused by dust pollution is not possible then.Our company provide two types of bucket elevator. One is NE type Bucket elevator, the other is DJY type belt bucket elevator.

NE type Bucket elevator with large throughput, great enhancing-height, stable and reliable operation, long life and other significant advantages. Hybrid-type or gravity discharge, earth-type loading. Application to transport packing density of less than 1.5t/m³, easy to take out the powder, granular, small block of low-mill cut materials, such as coal, cement ,gravel ,sand fertilizer, food and so on. Delivery temperature of the material does not exceed 250°C.

DJY series bucket elevator is specially used for continuous vertical conveying grain of equipment, its less occupied area, large conveying capacity, low power consumption. In oil, feed, flour, starch and other industries use is widespread, the series bucket elevator is according to the current situation of the bucket elevator at domestic and abroad, to absorb the advantages of similar products in the production of a new generation of bucket elevator, which can be widely used for vertical transportation of various granular materials.

Working Principle of Bucket Elevator

While powered on, the driving device (made by customer's requests) drives head pulley to make the bucket belt do the circular motion from bottom to up. The bucket is filled with material and conveyed to the head terminal, and then the material is thrown from the outlet under the action of centrifugal force according to the parabolic design. After discharging, the empty bucket is back to the boot by conveying and be filled again, and then lifted from bottom to the top to the specified height to reach conveying vertically.

Features of Bucket Elevator

1.Good sealing, less pollution.

2.convenient maintenance and operation, less easy-worn parts.

3.use low cost, since energy saving and less maintenance, use cost very little.

4.reliable operation, advanced design principle to guarantee the machine running reliability.

5.precision is high. The cabinet is compressed tightly by ruffled and middle parts, then after welding, rigid, appearance beautiful.

6.small machinery size, compared with other kinds of hoist which has the same lifting capacity, this hoist’s size is smaller.

7.big carrying ability. Lifting capacity is in the range15 ~ 800 m3 / h.

8.convenient operation, less maintenance, less easy-worn parts. Conveying chain sleeve roller chain, inducement gravity unloading, used in all kinds of powder, block grain of vertical lift.

Parameter of Bucket Elevator

Parameters of NE Type Plate Chain Bucket Elevator

| Item | Conveying capacity (m³/h) | Hopper | Max aggregate diameter (mm) | Spindle speed (r/s) | Material bulk density (t/m³) | Max hoisting height (m) | Power (kw) | |||

Volume (L) | Bucket chain pitch (mm) | Hopper width (mm) | Bucket speed (m/s) | |||||||

NE15 | 10~15 | 2.5 | 203.2 | 250 | 0.5 | 40 | 15.54 | 0.6~2.0 | 35 | 1.5~4 |

Parameters of DJY Type Belt Bucket Conveyor

| Model | Speed | Strong Belt Width | Bucket Distance | Bucket width | Volume | Total height | Lifting capacity | Motor power | Remark |

DJY38/25 | 2~3.5 m/s | 250 mm | 200~250 mm | 230mm | 1.6 L | 9.8m or as required | 20-25m3/h | 4kw | Motor powder changes with the total height |

Cell Phone: +86 15137175832

Whatsapp: +86 15137175832

Email: sunnydjy823@gmail.com

efficientservice@outlook.com

Address: Dejinyang company