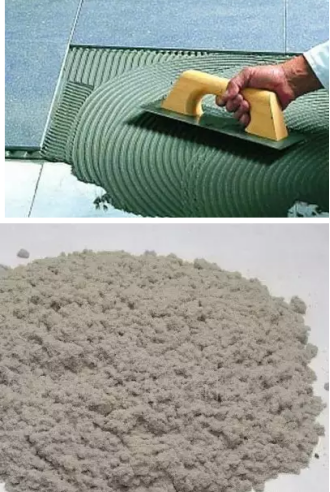

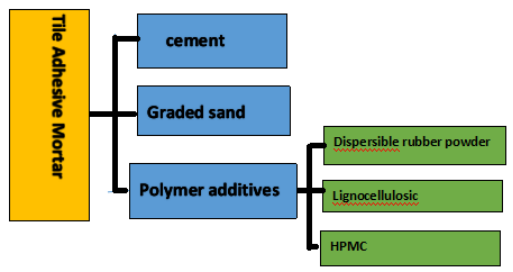

Bonding mortar It is made of cement, quartz sand, polymer binder and various additives evenly mixed by mechanical means. Adhesives used primarily for bonding insulation boards are also known as polymer bonded mortars. The adhesive mortar has excellent flexibility and bondability compared with the mortar mixed with the traditional construction adhesive, as well as good water retention, water resistance and convenient operation, and enhances the bond strength between the base material and the heat insulation board ,Strengthen the tensile strength, solve the problem of emptying, falling off and other quality problems.

1. Plasticizing and lubricating properties of bonding mortar:

High-molecular polymers have a strong binding force on water molecules and strongly adsorb moisture, thereby reducing the degree of freedom of water. At the same time, micro-bubbles are generated in the mortar. On the one hand, it can play a good role in lubrication and improve the fluidity and sag resistance of the mortar. On the other hand, it is also possible to suspend the aggregate and reduce the sinking of the aggregate, so that the mortar has a good plasticizing effect, which is also called mortar fullness, and is also an important indicator for improving the construction performance of the mortar.

2, Water retention thickener physical properties:

After adding water to the dry mortar, it is divided into combined water, lubricated water, and free water. In the part of the cement that reacts quickly, a hydration reaction occurs after water is added. The first part consumes water and cannot escape the mixture. This part of water is defined as Combined with water. After water encounters dry water, fine aggregates, and mineral materials, the surface of cement, fine aggregate, and mineral materials will absorb a portion of the water, making the dried material wet and unable to escape the mixture, but can be adjacent to the Water replacement, this part of the water is defined as moist water. The excess water in the mortar is free water and acts as a lubricant in the mortar. The fluidity and lubrication of the mortar depend to a large extent on the amount of free water. Therefore, the water retention rate in the mortar must meet the needs of the absorption of the base surface of the wall, the conservation of the mortar, and the loss of moisture due to weather and other factors. Therefore, the water retention rate of mortar is a key factor. It is to retain free water in the mortar to ensure the demand for hardening and curing of the mortar. Using a certain amount of fly ash and ultra-fine ore powder to increase the specific surface area of the material can also play a role in water retention. Increase the adsorption of moisture and minimize free water.

3, Shorten the construction time:

Water retention in mortar is important, but it will cause bonding mortar construction time to extend and affect construction efficiency. It will also increase the shrinkage rate. Therefore, reducing the amount of water added, and correspondingly reducing the amount of free water, so as to improve the quality of bonding mortar and shorten the construction time Increase workers' construction efficiency.

4, Effect of water retention rate on bonding mortar

The water retention rate of mortar is a very important indicator. The level of water retention will directly affect the shrinkage, bond strength and construction performance of bonding mortar.

1) Poor water retention can cause plastic cracking:

The water retention rate of mortar is poor, and moisture can easily be lost. Especially for the wall of aerated block that absorbs water quickly, the water is absorbed by the substrate, while the bonding mortar is not condensed and there is no tensile stress that can resist the volume shrinkage. The adhesive mortar is irregular Cracks.

2) Poor water retention may cause emptying:

Mortar bleeding can cause unevenness in the composition of the dry mortar, leading to a decrease in the overall performance of the tile bonding mortar. For masonry and plastering, the water is dispersed and lost, and the water is easily dissipated by the substrate. The cement is not fully hydrated and the mortar is reduced. Substrate adhesion. Under the change of temperature and humidity, the mortar will produce volume deformation and stress, which will cause the mortar to separate from the substrate. This phenomenon is the main reason for the emptying of bonding mortar.

3) Poor water retention rate and reduced workability:

Mortar water retention rate is poor, mortar bleeding occurs, the mortar in the mixing process after adding water or stratification occurs during the placement and the upper, middle, bottom layer consistency is different, resulting in poor cohesion, plaster easily fall ash, bonding mortar operation Poor sexual consequences.Therefore, while controlling the quality of raw materials, it is also necessary to choose mortar additives with good quality and complete functions to make up for the lack of adhesive mortar function, thereby enhancing the workability and adhesion of dry mortar, increasing the crack resistance of mortar, and reducing the permeability. The mortar is not easy to bleeding and separate, to meet the national performance indicators and construction performance indicators of dry mortar to ensure the quality of bonding mortar.

5, Dry Mortar preparation points

a. The sand used in the production must be sand after removing the particles with a particle size of 5mm or more after sifting, and ensure the correct use of raw material varieties and specifications.

b, strictly control the mixing time, each mixing should not be less than 2min.

c. The mixer metering system is strictly monitored during the production process to ensure the accuracy of the measurement.

6, Bonding Mortar logistics and storage control points

a. Stirring trucks should be used. Before filling, there should be no accumulation of water, accumulated pulp and sundries in the cylinder. It is forbidden to add water during transportation and unloading. During the transportation process, the cylinder rotates at a certain speed so that the homogeneity of the dry mortar remains unchanged.

b. The project name, location and strength grade of mortar specified in the delivery note shall be promptly and accurately transported.

c. After the mortar is transported to the construction site, it must be stored in a non-absorbent closed container, except for direct use, and be shaded, insulated, and protected from rain. The temperature of the storage location should not exceed 37°C, and should not be lower than 0°C.

d, storage containers should be clearly identified, to ensure the first use of the first use, is strictly prohibited the use of more than the setting time of the bonding mortar, mixing of different types of adhesive mortar is prohibited mixed. It is forbidden to empty the mortar in the tank, and the mortar in the tank should be fed in time to 8 tons to avoid segregation phenomenon.

e. The mortar must be used within the time specified in the contract.

f After the unloading, the mixer truck should be thoroughly cleaned.

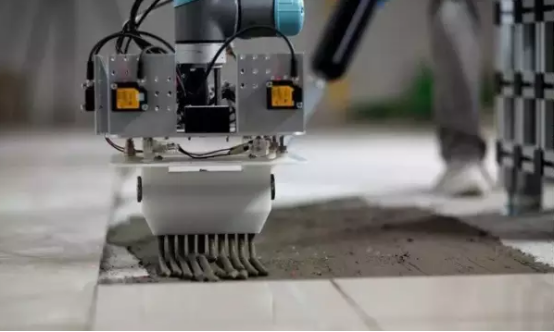

DJY Machinery Welcome to consult the dry mortar mixing production line or any questions about dry mortar !

Remark: the AUTOMATIC DRY MORTAR PLANT details:http://www.djyhn.com/product/15.html ;

manually dry mix mortar production line details: http://www.djyhn.com/product/16.html ;

Cell Phone: +86 15137175832

Whatsapp: +86 15137175832

Email: sunnydjy823@gmail.com

efficientservice@outlook.com

Address: Dejinyang company